When it comes to forestry mulching and land clearing, the cutting tools you run on your mulcher rotor have a huge impact on productivity, running costs, and overall machine performance.

Two of the most common options are planer knives and carbide mulcher teeth. While both have their place, they are designed for very different applications.

Understanding the differences will help you choose the right solution — and avoid unnecessary downtime and replacement costs.

What Are Planer Knives?

Planer knives are flat, hardened steel blades mounted to the rotor. They cut vegetation using a slicing action and are commonly used in lighter-duty mulching applications.

Best suited for:

- · Grass and brush

- · Light vegetation

- · Soft ground conditions

- · High-speed, low-resistance cutting

Advantages:

- · Lower upfront cost

- · Best shredding quality

- · Aggressive, fast mulching

- · Lightweight and easy to change

Limitations:

- · Wear quickly in abrasive conditions

- · Poor resistance to impact

- · Not suitable for rocky ground or hardwood

- · Require frequent replacement in demanding applications

Planer knives work well where material is soft and ground conditions are controlled. Once stone, roots, or hard soil are introduced, wear rates increase dramatically.

What Are Carbide Mulcher Teeth?

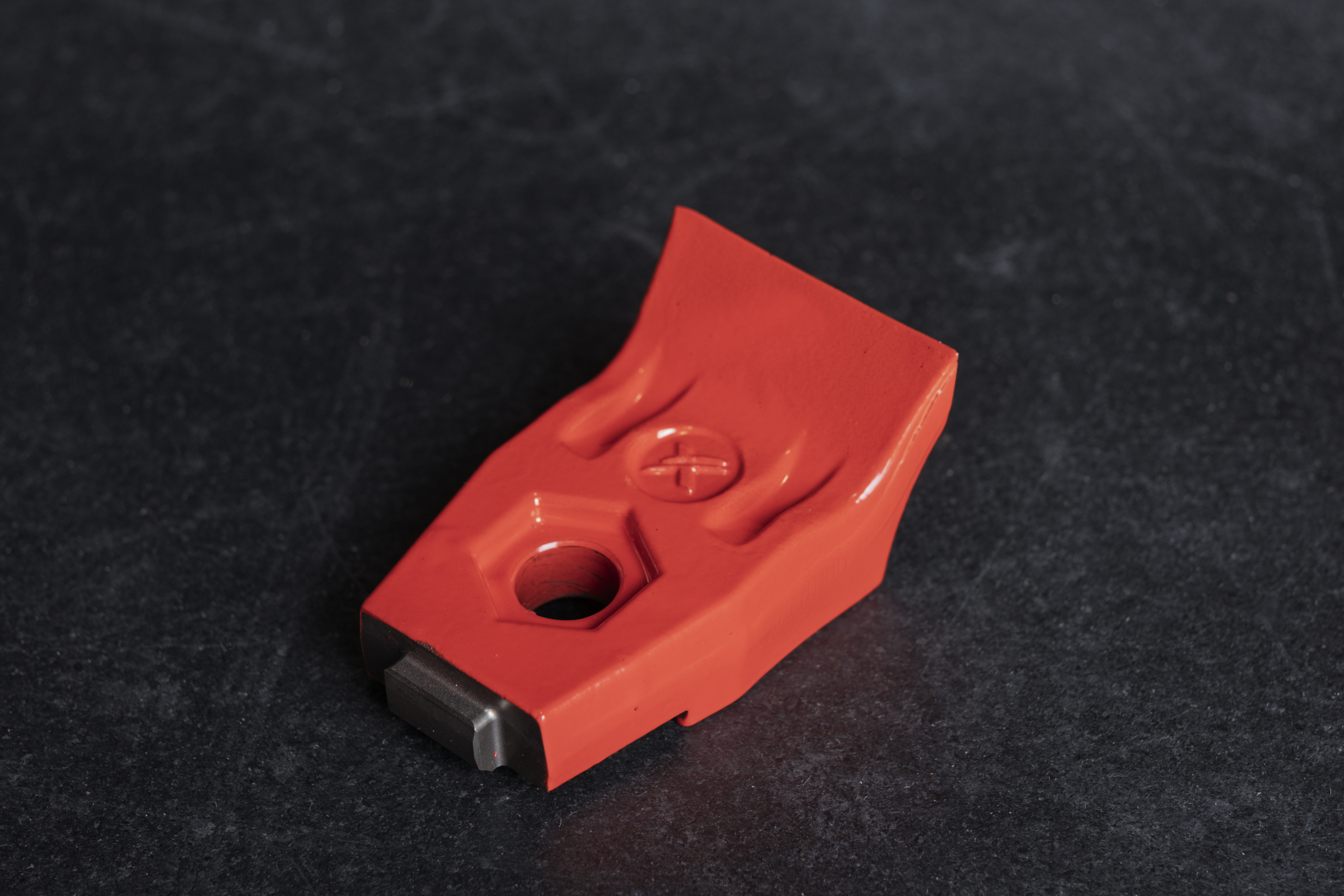

Carbide mulcher teeth use tungsten carbide inserts mounted in a heavy-duty steel body. The carbide provides extreme hardness and abrasion resistance, while the steel body absorbs impact.

Best suited for:

- · Forestry and land clearing

- · Hardwood and mixed vegetation

- · Abrasive or rocky terrain

- · Commercial and high-hour operations

Advantages:

- · Significantly longer service life

- · Excellent resistance to abrasion and impact

- · Consistent cutting performance over time

- · Reduced downtime and fewer change-outs

Things to consider:

- · Higher upfront cost compared to planer knives

- · Not always necessary for very light vegetation work

In real-world conditions, carbide teeth are designed to keep working where planer knives would rapidly wear or fail.

Performance in Real Jobsite Conditions

The key difference comes down to how each tool handles impact and abrasion.

- Planer knives rely on sharp steel edges, which dull quickly when exposed to soil, stone, or hard material.

- Carbide teeth are built to withstand repeated impact and abrasive wear, making them far more forgiving in unpredictable ground conditions.

For operators working in mixed terrain, carbide teeth offer reliability where planer knives often become a consumable item.

Cost Per Hour: The Metric That Matters

While planer knives are cheaper to purchase, they often cost more in the long run due to:

- Frequent replacements

- Increased downtime

- Additional labour costs

Carbide mulcher teeth are typically chosen by operators who focus on cost per hour, not just initial purchase price. Fewer replacements and longer service intervals quickly offset the higher upfront cost.

Why Many Operators Choose Carbide Teeth

As land clearing jobs become more demanding and ground conditions less predictable, many operators have moved away from planer knives in favour of carbide teeth.

Carbide teeth offer:

- Longer wear life

- Greater tolerance to operator variation

- Reduced maintenance intervals

- More consistent performance across different sites

Need Help Choosing the Right Carbide Teeth?

At Xtreme Wear Parts, we specialise in heavy-duty carbide mulcher teeth designed for demanding applications. Our team can help you match the right tooth to your machine, rotor, and terrain.